What Electrical Safety Devices Are Used for Protection of Workers?

Introduction

Electrical safety is one of the important aspects of workplace safety, especially in industries in which employees come first-hand with electrical systems. Electric shocks, burns, and even serious injuries through arc flashes are mainly hazardous applications of electricity that make it imperative to use safety equipment and safety rules. Safety for these devices also extends to the reliability of electrical systems as well as the potential cost effects due to accidents.

In this article, safety devices used for the protection of workers, the rules that guide their safe use, and innovative solutions such as EPOWER that will change the aspect of electrical safety will be discussed.

Electrical Protection Equipment

Electrical protection equipment is that which avails of itself as a first line of defense against hazard from the electrical systems of any sort-the work tool and devices, the injury prevention measures, or the tool that would be used for work where live electrical currents will be present. Probably, most common is Personal Protective Equipment or PPE, such items being insulated gloves, dielectric boots, and arc-rated clothes, all having a protective barrier from direct electrical exposure to the worker. PPE serves as a physical barrier so that the worker can carry out electrical duties freely, even within high-risk environments. There is provision for face shields and helmets too, which protect against possible arc flashes that cause severe burns and injuries.

The second most important category is circuit-protective devices such as circuit breakers and fuses. Such components automatically disconnect the electrical current in case of occurrence of any anomalies like short circuiting or overload. Other important devices among them are Residual Current Devices (RCDs) and ”surge suppressors,” works to inhibit external electric shocks and protect devices in a load from damage resulting from a power surge. In this way, these items together make sure that electrical systems are safe and workers at least will suffer injuries.

Safeguard Devices Protect Users from Injury

Accidents are prevented by these devices once a rapid response is adopted when irregularities are detected in an electrical system. This is essential in preventing injury, damage, or loss affecting workers, users, and even property.

Such a device is called Ground Fault Circuit Interrupter (GFCI). GFCIs are devices that monitor constant electric currents and disconnect power supply upon detecting any imbalance occurring from water exposure or leakage currents. As such, GFCIs prevent users from encountering very severe electrical shocks usually found in wet and damp places.

Another important one among them is the Arc Fault Circuit Interrupter (AFCI), which prevents fire resulting from the arc faults caused by either damaged wiring or loose connections. Other important safeguards include overload relays and emergency shut-off switches. Overload relays prevent the overheating of electrical equipment. An emergency switch would enable quick shutdown of power when a critical situation arises. Collectively, these devices enhance the safety level of the workplace through active mitigation of the potential hazards.

Electrical Safety Rules

For proper protection against hazards at the workplace, they have also established electrical safety rules along with protection devices for usage. Safety procedures are meant for managing and maintaining electrical systems by which protection can be guaranteed to both workers and equipment.

The commonest rule of them all is breaking down the appliance or equipment before maintenance or repair; this prevents electrocution as lockout/tagout makes it impossible to energize an appliance during maintenance. Test circuits even to ensure they are not energized before going to work on any task.

Another requirement is carrying out regular inspection and tests on all electrical systems. Using these available inspection results, preventive maintenance shall keep such systems reliable and avoid accidents. It is equally important to train the workers in the understanding and following of such rules to create safety-first culture all-round in the workplace.

Changing the Scenario of Electrical Safety with Smart Solutions by EPOWER

EPOWER has a novel way of treating electrical safety, which is quite different from the methods that buildings and workplaces use to address electrical hazards. By combining cutting-edge technological means with intelligent design features, EPOWER provides a comprehensive solution for preventing accidents and increasing operational safety.

Among these features is the live hazard detection. It uses thermal sensors and temperature-monitoring systems to identify the possible overheating of electrical circuits long before it becomes a serious problem. The proactive approach cuts back the chances of causing fires from faulty wiring or overloading an electrical circuit.

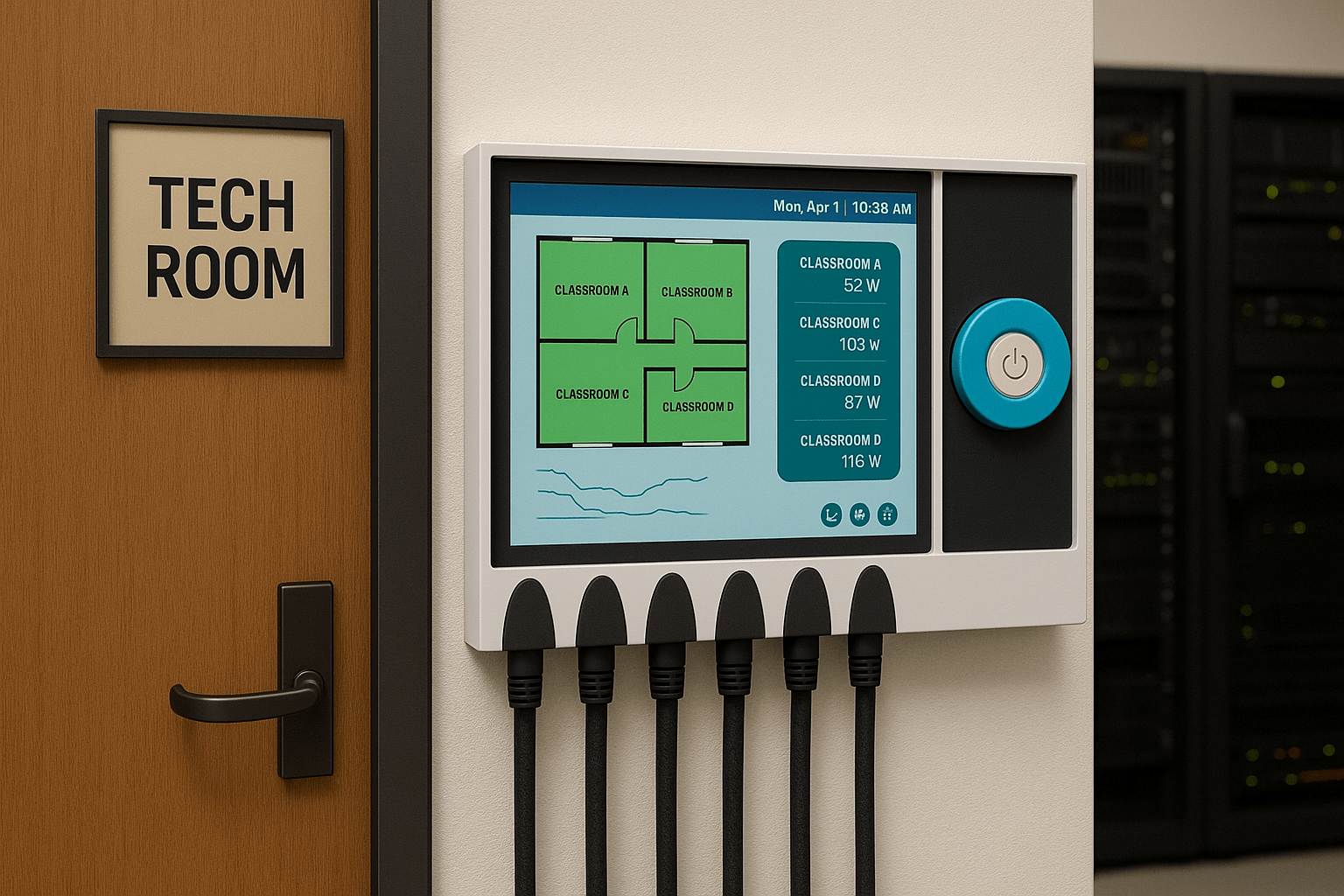

In addition to detection, EPOWER has an automated hazard prevention system. The system cuts off power to the affected circuit on detection of anomalies such as overheating and abnormal currents so as to avert damage and fatalities. This alerting system sends messages to the users’ smartphones concerning any occurrence, making them immediately aware of issues even when off-site. Furthermore, EPOWER perfectly integrates with the Building Management Systems (BMS) for centralized control and monitoring towards enhanced efficiency. The features, therefore, put EPOWER in the class of indispensable tools in the modern building in guaranteed safety and reliability.

Conclusion

These protect devices now with safety rules rating, and they require very continuous innovations to mitigate some risks about electrical safety. Some of those devices protect individuals while using the circuit interrupters like GFCIs and AFCIs as their safeguard devices with good protection against electrical hazards concerning even the safest safety rules available to ensure a safer work environment.

EPOWER’s smart solutions have taken electrical safety to the next level with real-time detection, automatic remedial response actions, and seamless integration with modern systems. With such advanced technologies, businesses can protect their employees and assets and help make electrical systems more efficient. Safety is not simply precaution; it is a pledge to the well-being of workers as well as the reliability of operations in the long haul.