E Power advancing proactive electrical safety

The reliability of modern electrical systems is not only a function of circuit design but also more advanced sensing technology that detects faults before they can do damage. Wire fires from overheating are still the number one risk around the world, and conventional protection schemes are limited in scope. Fuses and circuit breakers are reactive, they respond only after a surge has already flowed, and sometimes that is too late to prevent damage. This constraint has resulted in proactive electrical safety being an emerging new research requirement in engineering, particularly for high-demand applications such as Canadian structures that experience harsh winters augmenting load on heating systems.

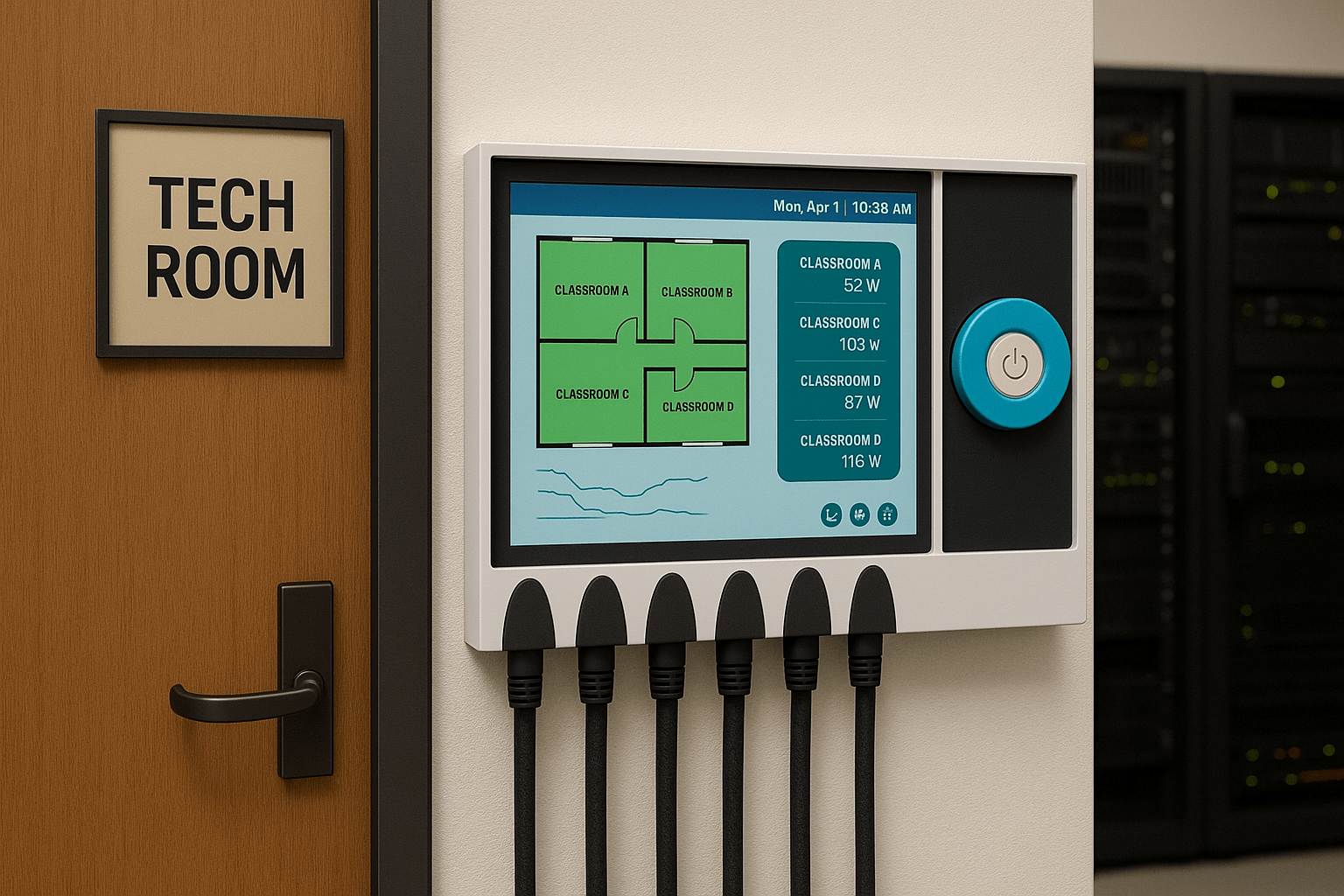

E Power surmounts this challenge through embedding thermal sensor innovation in building distribution boxes. Unlike traditional practice, its thermal sensors actively monitor small resistance variations and temperature rise according to Joule’s Law (P = I²R). This scientific approach allows fault identification at the initial stage as well as precise intervention. Through focus on electrical heating physics, E Power demonstrates how advanced monitoring can drastically revolutionize safety procedures in modern infrastructures.

Physics of Electrical Overheating

Central to proactive electrical safety is familiarity with electrical heating theory. Current flowing through a conductor warms due to resistance, with the magnitude being proportional to the square of the current. Small increases in current over time can lead to conductor temperatures becoming unsafe. This subtle process is dangerous since insulation degradation and material fatigue accumulate without being noticed.

Thermal sensor innovation allows real-time imaging of these heat gradients, lighting hidden threats. With the incorporation of sensors in distribution boxes, E Power captures precise up-to-the-minute data rather than delayed signals like sparks or smoke. Such science accuracy ensures that intervention is triggered at the first possible moment, essentially closing the window left by reactive devices. In Canadian environments where seasonal loads fluctuate wildly, this specificity is vital to preventing catastrophic failures.

Thermal Sensor Innovation in Practice

The thermal sensor innovation design employed in E Power is based on infrared thermography and micro-electromechanical systems (MEMS). The technologies can sense even minor increases in heat on conductor surfaces. As soon as information shows a deviation, algorithms calculate the amount and predict potential ignition risks.

This approach keeps pace with technological advancement in materials sciences, where sensors are optimized for toughness and sensitivity in hostile environments. Infrared detection creates a backup layer beyond thermal sensing by picking up hotspots beyond points of direct contact, making it a redundant safety net. With the accuracy of MEMS technology and infrared imaging, E Power positions itself as a leader in proactive electrical safety, offering reliability beyond that of standard monitoring systems.

Proactive Algorithms for Safety Intervention

Hardware alone cannot ensure proactive electrical safety; algorithms also play a crucial role. E Power integrates machine learning techniques that analyze thermal profiles over time. They identify abnormal patterns, including resistance over time increases in aging wires, and take action before limits are exceeded.

This strategy mimics predictive maintenance practice that is prevalent in industrial engineering. Continuous data feeds from thermal sensor innovation form the bases of predictive modeling in real time. Instead of responding to failures, the system forecasts potential hazards and disposes of them ahead of time. This scientific methodology ensures intervention is not arbitrary but evidence-based, pegged on quantifiable data. In the case of old electrical infrastructure in Canadian buildings, predictive algorithms are indispensable to reducing the risk of fire.

Material Science and Sensor Reliability

Thermal sensor innovation depends greatly upon material properties. The sensors are designed to withstand thermal cycling, mechanical stress, and electromagnetic interference. New polymer composites and ceramics enhanced durability and response accuracy. With a selection of materials with high thermal conductivity and stability, E Power ensures prolonged operation under extreme conditions.

For the Canadian markets, reliability of materials is particularly important due to the severe inter-seasonal temperature variations. The capacity of sensors to endure such stresses defines the value of proactive electrical safety devices. This reflects a universal scientific principle: that long-term stability of materials when under stress dictates real-world safety performance. With carefully crafted sensor elements, E Power tackles this challenge directly.

Broader Scientific and Market Implications

Thermal sensor innovation is used throughout electrical fire prevention. Scientific research in this field contributes to broader scientific goals, such as predictive information for smart infrastructure and integration of Internet of Things (IoT) networks. Sensors are embedded into everyday systems, turning buildings into data-intensive spaces that can self-optimize.

In the Canadian smart building sector, such developments collaborate with sustainability goals, insurance requirements, and national safety codes. Proactive electrical safety is no longer optional; it is central to resilience planning for homes and businesses. E Power is a case in point for where science meets market, demonstrating how applied research in thermal sensing translates directly to safer communities and smarter infrastructure.

Conclusion

Scientific breakthroughs in sensing technologies have transformed the way we address electrical safety. Traditional protection devices, as much as they are needed, cannot prevent against the sneaky accumulation of heat that normally triggers fires. With advanced thermal sensor innovation, such as with E Power, safety is now redefined from a reaction to prevention.

The intersection of reliable thermal sensing, algorithmic forecasting, and materials science represents the essence of proactive electrical safety. With them, Canadian structures, with their unique climate and infrastructure requirements, can realize smart and hardened electrical systems. Besides real-time security, such innovation insures the smart building industry by injecting scientific rigor into regular infrastructure.

Fundamentally, E Power is as much a product as it is a scientific solution to one of the most severe problems facing building management today. It is prevention-based, founded on measurable physics and advanced engineering principles that establish a new standard of safety in Canada and beyond.